Enquiry Form

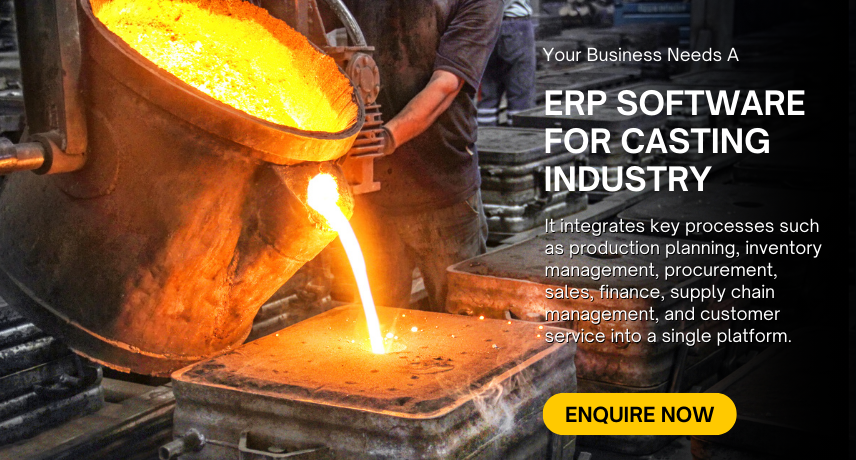

What is ERP Software For Casting Industry?

ERP (Enterprise Resource Planning) software for the casting industry is a specialized solution designed to manage and streamline operations in foundries, die-casting units, and metal casting businesses. It integrates critical processes such as production planning, inventory management, quality control, procurement, sales, finance, and supply chain management into a single platform.

What are the Best 15 Features of ERP Software For Casting Industry?

Here Are Top 15 Features of ERP Software For Casting Industry

Production Planning & Scheduling:

Manages work orders, resource allocation, and job scheduling.

Bill of Materials (BOM) Management:

Tracks multi-level product structures and alloy compositions.

Raw Material & Inventory Control:

Monitors metals, alloys, and scrap materials in real-time.

Mold & Pattern Management:

Maintains mold inventory, reuse tracking, and lifecycle management.

Melting & Alloy Composition Control:

Ensures accurate chemical composition and material quality.

Quality Assurance & Compliance:

Conducts material testing, defect tracking, and regulatory adherence.

Procurement & Supplier Management:

Automates purchasing, vendor selection, and order tracking.

Costing & Financial Management:

Tracks production costs, scrap value, and financial reporting.

Waste & Scrap Management:

Monitors metal wastage, scrap utilization, and recycling processes.

Machine Maintenance & Downtime Reduction:

Schedules preventive maintenance for equipment longevity.

Sales & Order Management:

Tracks quotations, order processing, and customer deliveries.

Multi-Location & Multi-Plant Support:

Centralized control for foundries and casting units across locations.

Business Intelligence & Analytics:

Provides real-time reporting for better decision-making.

User Access & Security:

Implements role-based access control for data security.

Cloud & Mobile Accessibility:

Enables remote monitoring and real-time data access via cloud ERP.

Benefits of ERP Software For Casting Industry

Here Are Top Benefits of ERP Software For Casting Industry

- Improved Production Efficiency: Automates workflow, job scheduling, and resource planning.

- Optimized Inventory Management: Tracks raw materials, alloys, and scrap in real-time.

- Enhanced Quality Control: Ensures defect tracking, material testing, and compliance adherence.

- Cost Reduction: Minimizes waste, controls production costs, and improves profitability.

- Better Supply Chain Management: Streamlines procurement, vendor tracking, and order fulfillment.

- Reduced Machine Downtime: Schedules preventive maintenance for uninterrupted operations.

- Real-Time Business Insights: Provides analytics and reports for better decision-making.

Which Businesses Need ERP Software for the Casting Industry?

ERP software is essential for managing large-scale casting operations and ensuring efficient production workflows.

- Production Planning: Optimize raw material usage and reduce waste in casting processes.

- Real-Time Process Monitoring: Track molten metal pouring, cooling, and finishing stages.

- Inventory Management: Maintain stock levels for metals, alloys, and molds.

- Quality Assurance: Automate defect detection and ensure compliance with industry standards.

- Equipment Maintenance: Schedule preventive maintenance for furnaces, molds, and machinery.

- Order and Dispatch Management: Streamline customer orders, shipment tracking, and delivery schedules.

ERP helps small and medium-sized foundries manage operations efficiently while keeping costs under control.

- Cost-Effective ERP Solutions: Scalable and affordable software tailored for smaller production units.

- Job Scheduling: Allocate resources effectively to maximize production efficiency.

- Raw Material Tracking: Monitor metal stock and minimize wastage.

- Simplified Invoicing and Billing: Automate financial transactions and tax calculations.

- Workforce Management: Track labor hours, shifts, and productivity.

- Regulatory Compliance: Ensure adherence to environmental and safety standards.

ERP software enhances efficiency in specialized casting operations like die casting and investment casting.

- Process Automation: Streamline mold design, casting, and finishing.

- CAD/CAM Integration: Connect ERP with design software for seamless workflow.

- Quality Control Tools: Ensure high precision in metal casting with real-time inspections.

- Supply Chain Visibility: Track material procurement and supplier performance.

- Energy Consumption Monitoring: Optimize energy usage in heating and melting processes.

- Customer Order Management: Handle custom casting requirements and delivery schedules.

Casting manufacturers in the automotive and aerospace industries require advanced ERP systems to manage high-performance components.

- Advanced Material Management: Track high-grade alloys and composite materials.

- Precision Engineering: Ensure dimensional accuracy with real-time monitoring.

- Regulatory Compliance: Maintain ISO, AS9100, and other industry certifications.

- Multi-Plant Operations Management: Centralize data across multiple foundries and production units.

- Supply Chain Optimization: Improve coordination between raw material suppliers and manufacturers.

- Customer Relationship Management (CRM): Manage long-term contracts and customer-specific production schedules.

ERP software helps metal casting industries maintain efficiency, reduce costs, and ensure quality.

- Batch Production Management: Track production batches from melting to final inspection.

- Scrap and Waste Management: Optimize recycling and reusability of metal waste.

- Furnace and Kiln Monitoring: Automate temperature and process control for consistent casting quality.

- Logistics and Supply Chain: Streamline raw material procurement and finished goods distribution.

- Financial Reporting: Gain insights into profitability, material costs, and operational expenses.

- Predictive Maintenance: Schedule equipment maintenance to avoid downtime.

How to Choose the Best ERP Software For Casting Industry

- Identify Business Needs: Assess production, inventory, quality control, and compliance requirements.

- Industry-Specific Features: Look for BOM management, melting control, and scrap management.

- Deployment Model: Choose cloud, on-premise, or hybrid ERP based on scalability and security.

- Customization & Scalability: Ensure adaptability to future growth and process-specific modifications.

- User-Friendliness & Training: Opt for an intuitive interface with training and support options.

- Cost & ROI Analysis: Compare software pricing, hidden costs, and long-term return on investment.

- Vendor Reputation & Support: Check industry experience, customer reviews, and 24/7 support availability.

Boost Efficiency in the Casting Industry with Advanced ERP Software

Discover how ERP software tailored for the casting industry streamlines production, improves quality control, and enhances operational efficiency for manufacturers.

Latest News

Stay updated with latest industry information