Enquiry Form

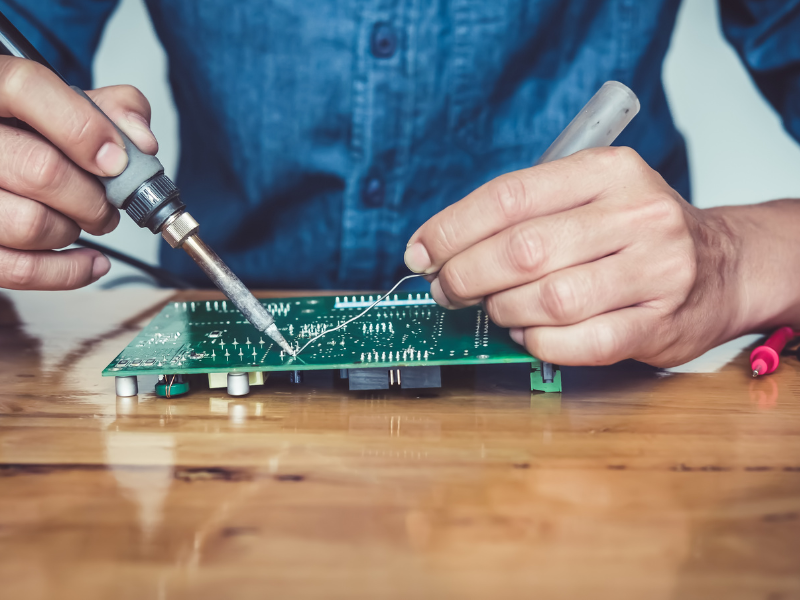

What is Manufacturing Software?

Manufacturing Software is a specialized solution designed to streamline and optimize production processes in the manufacturing industry. It integrates various functions, such as production planning, inventory control, supply chain management, and quality assurance, into a unified system. By automating workflows and providing real-time insights, Manufacturing Software enhances operational efficiency, reduces costs, and improves product quality, empowering manufacturers to meet demand effectively and stay competitive.

What are the Best Features of Manufacturing Software?

Here are 15 essential features of Manufacturing Software that revolutionize production processes:

Production Planning and Scheduling:

Optimize production schedules to meet deadlines and maximize resource utilization.

Inventory Management:

Track raw materials and finished goods in real time to prevent stockouts or overstocking.

Bill of Materials (BOM):

Create and manage detailed BOMs for accurate production planning.

Quality Control:

Implement quality checks at every stage of production to ensure product standards.

Supply Chain Management:

Monitor procurement, vendor performance, and logistics for streamlined operations.

Shop Floor Control:

Gain real-time visibility into shop floor activities and equipment status.

Work Order Management:

Automate the creation and tracking of work orders for better workflow management.

Cost Tracking:

Analyze production costs to identify opportunities for savings.

Machine Maintenance:

Schedule preventive maintenance to minimize downtime and extend equipment lifespan.

Real-Time Reporting:

Generate detailed reports on production efficiency, output, and downtime.

Integration with ERP Systems:

Sync with enterprise resource planning systems for unified operations.

Analytics and Forecasting:

Leverage predictive analytics to forecast demand and optimize production schedules.

Compliance Management:

Ensure adherence to industry standards and regulatory requirements.

Customizable Dashboards:

Access key metrics and insights through user-friendly dashboards.

Mobile Accessibility:

Monitor and manage production processes on the go with mobile-friendly features.

Benefits of Manufacturing Software

Here are eight key benefits of implementing Manufacturing Software:

- Improved Efficiency: Automate workflows to reduce manual effort and boost productivity.

- Enhanced Product Quality: Maintain consistent quality through automated quality control checks.

- Cost Reduction: Optimize resource utilization and minimize wastage to cut costs.

- Real-Time Insights: Access up-to-date production data for informed decision-making.

- Scalability: Adapt the software to support growing production volumes and complex processes.

- Better Collaboration: Foster communication and coordination across teams and departments.

- Regulatory Compliance: Stay compliant with industry standards and legal requirements.

- Customer Satisfaction: Deliver high-quality products on time, enhancing customer trust and loyalty.

Which Businesses Need Manufacturing Software?

Manufacturing Software is essential for businesses in various manufacturing sectors. Here’s how it serves different industries:

- Production Line Optimization: Streamline production lines for faster output.

- Inventory Tracking: Monitor parts and components for efficient assembly.

- Quality Assurance: Ensure compliance with safety and quality standards.

- Supplier Management: Maintain strong relationships with suppliers for timely deliveries.

- Cost Analysis: Track and reduce production costs for better profitability.

- Batch Tracking: Monitor batches to ensure product consistency and traceability.

- Shelf Life Management: Track expiration dates to minimize waste.

- Regulatory Compliance: Adhere to food safety regulations and labeling requirements.

- Recipe Management: Manage and optimize recipes for consistent product quality.

- Demand Forecasting: Predict demand to align production schedules with market needs.

- Order Management: Streamline order processing and production timelines.

- Inventory Control: Track fabric, trims, and finished goods accurately.

- Workflow Automation: Automate cutting, sewing, and finishing workflows.

- Product Customization: Manage customization requests efficiently.

- Cost Optimization: Monitor material and labor costs to maintain profitability.

- Batch Production: Track and document batch production processes for compliance.

- Quality Control: Implement stringent quality checks to meet regulatory standards.

- Inventory Management: Monitor raw materials and finished goods for effective supply chain management.

- Regulatory Adherence: Ensure compliance with GMP and FDA regulations.

- Process Optimization: Optimize production schedules to meet market demand.

- Component Tracking: Monitor components and assemblies in real time.

- Precision Manufacturing: Ensure high precision and minimal defects during production.

- Supplier Integration: Collaborate with suppliers for timely delivery of critical components.

- Production Analytics: Use real-time data to optimize processes and reduce downtime.

- Quality Management: Maintain rigorous quality standards to meet industry requirements.

How it Works

- Setup and Configuration: Customize the software to align with your production workflows and goals.

- Data Integration: Connect with existing ERP, inventory, and supply chain systems for unified operations.

- Production Management: Plan and schedule production tasks efficiently with automated tools.

- Real-Time Monitoring: Track production processes, equipment status, and inventory levels in real time.

- Quality Control: Implement automated quality checks at key production stages.

- Reporting and Analysis: Generate reports to evaluate production performance and identify areas for improvement.

Streamline Your Production with Smart Manufacturing Software

Simplify production, improve inventory control, and streamline operations with advanced manufacturing software tailored for growing businesses. Make smarter decisions and scale with confidence.

Latest News

Stay updated with latest industry information

FAQ's for Manufacturing Software

Here Are Some FAQs for Manufacturing Software