Enquiry Form

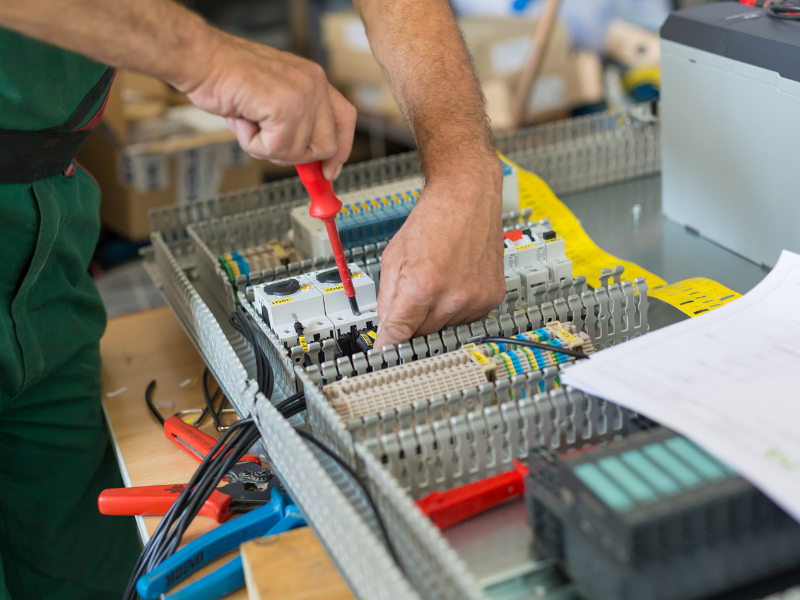

What is ERP software for Discrete Manufacturing?

ERP (Enterprise Resource Planning) software for Discrete Manufacturing is a specialized system that manages and optimizes production processes where distinct, countable products are manufactured. Unlike process manufacturing, which deals with formulas and bulk production, discrete manufacturing involves assembling or fabricating individual units such as machinery, automobiles, electronics, or aerospace components.

What are the Best Features of ERP software for Discrete Manufacturing?

Here Are 15 Best Features of ERP software for Discrete Manufacturing

Production Planning & Scheduling:

Optimizes resource allocation and minimizes downtime.

Bill of Materials (BOM) Management:

Tracks components, raw materials, and subassemblies.

Inventory Control:

Ensures real-time stock tracking and prevents shortages or excess inventory.

Supply Chain Management:

Streamlines procurement, vendor management, and logistics.

Work Order Management:

Automates job assignments and monitors production progress.

Quality Management:

Ensures compliance with industry standards through automated checks.

Cost Estimation & Control:

Analyzes production costs, labor expenses, and overheads.

Shop Floor Management:

Provides real-time monitoring of manufacturing processes.

Sales & Order Management:

Handles customer orders, quotations, and delivery schedules.

Material Requirement Planning (MRP):

Automates procurement based on demand forecasting.

Product Lifecycle Management (PLM):

Integrates design, development, and manufacturing processes.

Machine Maintenance & Asset Management:

Tracks equipment performance and schedules maintenance.

Real-time Analytics & Reporting:

Provides insights for data-driven decision-making.

Integration with CAD & IoT:

Connects design software and smart manufacturing technologies.

Multi-location & Multi-currency Support:

Enables global operations management.

Benefits of ERP for Discrete Manufacturing

- Improved Production Planning: Streamlines scheduling, resource allocation, and order management.

- Enhanced Inventory Control: Reduces waste and optimizes stock levels with real-time tracking.

- Better Quality Management: Ensures compliance with industry standards through automated quality checks.

- Cost Efficiency: Minimizes operational costs by optimizing procurement, labor, and material usage.

- Seamless Data Integration: Connects departments like procurement, sales, and production for better coordination.

- Faster Time-to-Market: Accelerates product development cycles with efficient workflow automation.

- Real-Time Decision Making: Provides actionable insights with advanced reporting and analytics.

Which Businesses Need ERP Software for Discrete Manufacturing?

ERP software for Discrete Manufacturing is essential for businesses that produce distinct items such as electronics, machinery, and consumer goods. It helps manage production, inventory, and quality control.

Companies producing vehicles, aircraft, or related parts rely heavily on ERP software to manage complex production processes.

- Production Planning: Manage assembly lines, component tracking, and quality checks.

- Inventory Control: Track individual parts, raw materials, and finished goods.

- Compliance Management: Ensure adherence to ISO, AS9100, and other industry standards.

- Supplier Collaboration: Streamline communication with vendors for timely part deliveries.

- Traceability: Track serial numbers for warranty, recalls, and maintenance history.

ERP solutions help manage intricate supply chains and ensure precision in product assembly.

- Bill of Materials (BOM): Organize complex product structures with multiple components.

- Demand Forecasting: Predict sales trends and manage inventory efficiently.

- Product Lifecycle Management (PLM): Manage design revisions, updates, and releases.

- Quality Control: Ensure defect-free production with automated inspections.

- Order Fulfillment: Manage bulk orders and customized product configurations.

These businesses produce specialized equipment, requiring precise tracking and resource management.

- Work Order Management: Automate job scheduling and production workflows.

- Inventory Management: Track raw materials, tools, and finished equipment.

- Maintenance Scheduling: Automate preventive maintenance for machinery.

- Document Control: Manage CAD drawings, blueprints, and technical specifications.

- After-Sales Service: Manage equipment warranties and spare parts distribution.

ERP software supports customized product design, production tracking, and delivery management.

- Custom Order Management: Manage customer-specific designs and custom furniture orders.

- Material Optimization: Minimize material waste and improve cost control.

- Production Scheduling: Plan production timelines and resource allocation.

- Inventory Management: Track wood types, finishing materials, and hardware supplies.

- Delivery Coordination: Manage dispatch schedules and ensure timely deliveries.

These businesses require strict quality control, traceability, and compliance management.

- Regulatory Compliance: Ensure adherence to FDA, ISO 13485, and other standards.

- Batch and Lot Tracking: Enable traceability for medical device recalls.

- Quality Assurance: Manage inspections, certifications, and audits.

- Supply Chain Visibility: Track components sourced from multiple suppliers.

- Document Management: Store product manuals, certifications, and testing records.

How to Choose the Best ERP for Discrete Manufacturing

Selecting the right ERP optimizes production, enhances efficiency, and ensures seamless manufacturing operations.

- Industry-Specific Features: Ensure the ERP supports BOM management, MRP, and shop floor control.

- Scalability & Flexibility: Choose a system that grows with your business and adapts to changing needs.

- Integration Capabilities: Ensure compatibility with CAD, IoT, and other essential manufacturing tools.

- Real-Time Data & Analytics: Look for advanced reporting and AI-driven insights for better decision-making.

- User-friendly interface: Opt for intuitive navigation and ease of use for faster adoption.

- Cloud vs. On-Premise: Decide based on security, accessibility, and cost considerations.

- Vendor Support & Training: Ensure reliable customer service, training, and ongoing updates.

ERP Software for Discrete Manufacturing | Optimize Your Production Workflow

Streamline your discrete manufacturing process with our industry-specific ERP software. Manage BOMs, work orders, inventory, production schedules, and quality control with ease.

Latest News

Stay updated with latest industry information