Enquiry Form

What is ERP Software for Sheet metal Industry ?

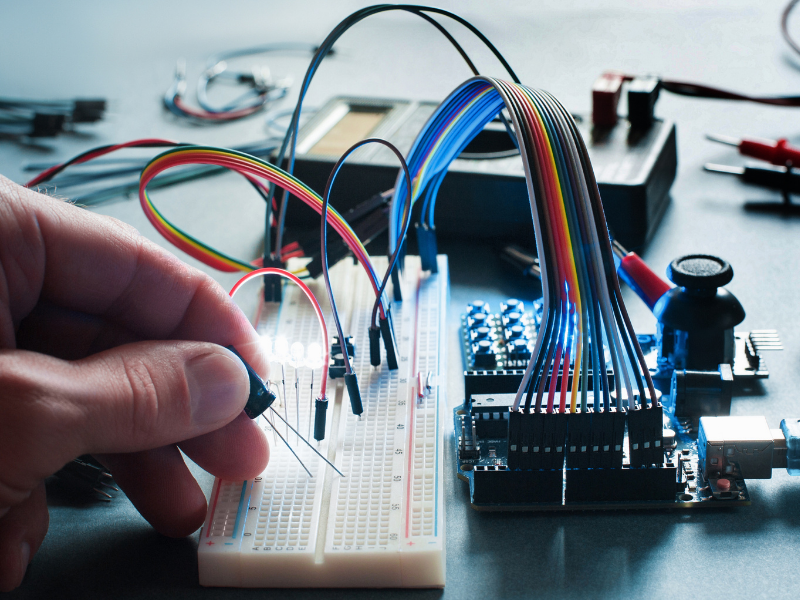

ERP (Enterprise Resource Planning) software for the sheet metal industry is a specialized solution designed to manage and streamline operations such as production planning, inventory control, material tracking, job scheduling, costing, quality management, and supply chain coordination. This software helps sheet metal manufacturers optimize processes like cutting, bending, welding, stamping, and finishing while ensuring efficient material utilization and compliance with industry standards.

What are the Best Features of ERP for Sheet metal Industry??

Here Are 15 Best Features of ERP for Sheet metal Industry

Production Planning & Scheduling:

Automates job orders, process sequencing, and resource allocation.

Material Requirement Planning (MRP):

Manages raw materials, sheet metal, and procurement processes.

Inventory & Warehouse Management:

Tracks stock levels, finished goods, and scrap material utilization.

Job Costing & Estimation:

Calculates material, labor, and overhead costs for accurate pricing.

Bill of Materials (BOM) Management:

This handles multi-level BOM for complex sheet metal assemblies.

Machine & Tool Maintenance:

Schedules preventive maintenance to avoid downtime and breakdowns.

Quality Control & Compliance:

Ensures defect tracking, testing, and industry standard adherence.

Order & Sales Management:

Manages quotations, customer orders, and delivery tracking.

Supply Chain & Vendor Management:

Streamlines procurement, supplier coordination, and purchase orders.

Real-Time Production Monitoring:

Tracks machine utilization, job progress, and operator efficiency.

Workforce & Labor Management:

Assigns tasks, tracks productivity, and manages workforce allocation.

Wastage & Scrap Management:

Monitors material wastage, scrap recycling, and cost control.

Business Intelligence & Reporting:

Provides real-time dashboards, analytics, and performance insights.

Cloud & Mobile Accessibility:

Enables remote access and real-time monitoring from any location.

Integration with CAD/CAM & CNC Machines:

Connects ERP with design and manufacturing systems for seamless operations.

Benefits of ERP Software for Sheet metal Industry

- Optimized Production Workflow: Automates job scheduling, cutting, bending, and welding processes.

- Efficient Material Management: Tracks sheet metal, coils, and raw material usage to minimize waste.

- Accurate Job Costing: Provides real-time cost estimation for labor, materials, and overhead.

- Enhanced Quality Control: Ensures defect tracking, compliance with industry standards, and process monitoring.

- Improved Inventory Management: Manages stock levels, order tracking, and warehouse operations.

- Streamlined Supply Chain: Automates procurement, vendor coordination, and delivery schedules.

- Real-Time Data & Reporting: Provides analytics for better decision-making and production forecasting.

Which Businesses Need ERP Software for the Sheet Metal Industry?

ERP software for the Sheet Metal Industry helps manufacturers manage production, inventory, quality control, and supply chain operations efficiently. Various businesses in this industry can benefit from ERP solutions.

Sheet metal fabrication businesses rely on ERP systems to streamline operations and enhance production efficiency.

- Production Planning: Optimize workflow with automated job scheduling.

- Material Management: Track raw materials like steel, aluminum, and copper.

- Cost Estimation: Automate cost calculation for different metal sheets and processes.

- Custom Order Management: Handle custom specifications for cutting, bending, and welding.

- Real-Time Monitoring: Track machine performance and minimize downtime.

Automotive and aerospace industries use sheet metal ERP software to manage complex supply chains and ensure precision manufacturing.

- Supplier Integration: Streamline procurement of high-quality metal sheets.

- Compliance Management: Ensure adherence to industry standards (ISO, AS9100).

- Inventory Optimization: Maintain adequate stock levels to prevent shortages.

- Product Lifecycle Management: Track components from design to final production.

- Quality Control: Ensure precise tolerances with automated inspections.

Construction businesses rely on ERP solutions to manage sheet metal usage in buildings, bridges, and other infrastructure projects.

- Project Costing: Estimate costs based on material usage and labor.

- Supply Chain Coordination: Ensure timely delivery of metal components.

- Inventory Management: Track sheet metal stock for different projects.

- Order Fulfillment: Automate procurement and scheduling for large-scale projects.

- Document Management: Store and manage blueprints, designs, and compliance documents.

Companies manufacturing electrical enclosures, panels, and components use ERP software to ensure precision manufacturing and quality.

- Production Scheduling: Automate job assignments based on deadlines.

- Custom Order Processing: Manage customized sheet metal casings and housings.

- Waste Reduction: Optimize material cutting to reduce scrap.

- Traceability: Track each component through its production cycle.

- Regulatory Compliance: Ensure adherence to electrical safety standards.

HVAC manufacturers use ERP software to optimize metal sheet cutting, bending, and assembly for ducts, vents, and other components.

- Design and Prototyping: Integrate CAD tools for seamless design transfer.

- Production Efficiency: Automate cutting and shaping processes.

- Material Tracking: Monitor different grades and thicknesses of sheet metal.

- Order and Delivery Management: Track orders from manufacturing to installation.

- Customer Relationship Management (CRM): Manage contracts, service schedules, and client interactions.

How to Choose the Best ERP Software for Sheet metal Industry

- Industry-Specific Features: Ensure support for production planning, MRP, BOM, and job costing.

- Customization & Scalability: Choose an ERP that adapts to your unique workflows and future growth.

- Integration Capabilities: Ensure seamless connectivity with CAD/CAM, CNC machines, and automation tools.

- Real-Time Data & Analytics: Look for live dashboards, production tracking, and performance insights.

- Inventory & Supply Chain Management: Ensure efficient material tracking, vendor management, and procurement automation.

- Cloud & Mobile Accessibility: Opt for ERP with remote access for real-time monitoring and control.

- Vendor Support & Implementation: Select a reliable provider with strong customer support and training services.

Best ERP Software for Sheet Metal Industry | Streamline Production & Boost Efficiency

Discover the top ERP software solutions tailored for the sheet metal industry. Improve operations, reduce waste, and enhance productivity with industry-specific ERP tools.

Latest News

Stay updated with latest industry information