Enquiry Form

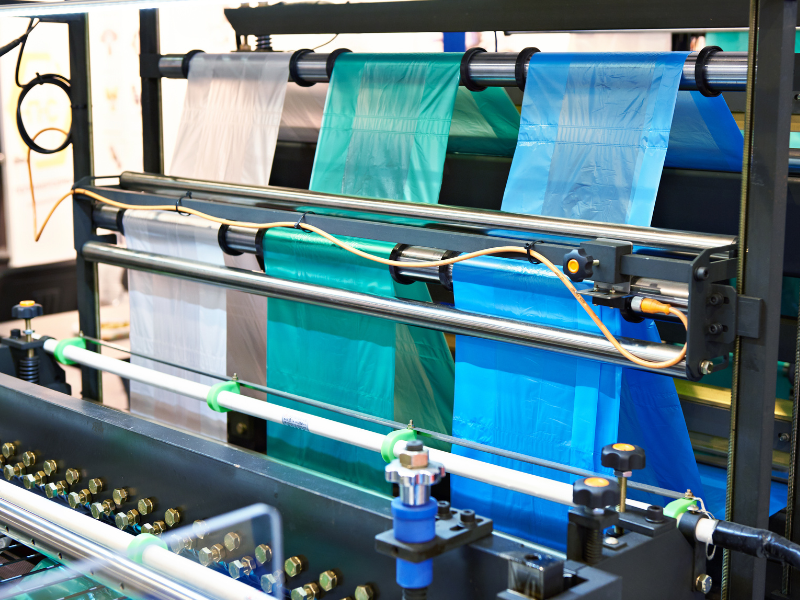

What is ERP Software for the Plastic Moulding Industry??

ERP (Enterprise Resource Planning) software for the plastic moulding industry is a specialized system designed to manage and streamline operations in injection moulding, blow moulding, extrusion, thermoforming, and rotational moulding businesses. It integrates key processes like production planning, inventory management, quality control, procurement, sales, finance, and machine maintenance into a unified platform.

What are the Best Features of ERP for the Plastic Moulding Industry?

Here Are The Best 15 Features of ERP for the Plastic Moulding Industry

Production Planning & Scheduling:

Automates moulding cycles, work orders, and job scheduling.

Raw Material Management:

Tracks polymers, resins, additives, and colorants in real-time.

Mould & Tooling Management:

Monitors mould lifecycle, maintenance, and reusability.

Inventory & Warehouse Control:

Manages raw materials, semifinished, and finished goods efficiently.

Quality Control & Compliance:

Ensures defect tracking, material testing, and regulatory compliance.

Machine & Equipment Maintenance:

Schedules preventive maintenance to minimize downtime.

Waste & Scrap Management:

Optimizes raw material usage and reduces production waste.

Costing & Financial Management:

Tracks production costs, pricing, and profitability analysis.

Order & Sales Management:

Manages customer orders, quotations, and real-time order tracking.

Supply Chain & Procurement:

Automates supplier selection, purchasing, and vendor management.

Multi-Location & Multi-Plant Support:

Centralized control for manufacturing units across locations.

Business Intelligence & Reporting:

Provides real-time analytics and performance tracking.

User Access & Security:

Implements role-based access control to protect business data.

Cloud & Mobile Accessibility:

Allows remote monitoring and real-time ERP access.

Integration with CAD/CAM & IoT:

Connects with design software and IoT-enabled machines for efficiency.

Benefits of ERP for the Plastic Moulding Industry

- Improved Production Efficiency: Automates moulding cycles, work orders, and scheduling.

- Optimized Inventory Management: Tracks raw materials, polymers, and finished goods in real-time.

- Enhanced Quality Control: Reduces defects, ensures compliance, and maintains product consistency.

- Reduced Material Waste: Minimizes scrap and optimizes raw material utilization.

- Better Machine Maintenance: Schedules preventive maintenance to reduce downtime.

- Streamlined Supply Chain: Automates procurement, vendor tracking, and order management.

- Real-Time Business Insights: Provides analytics and reports for informed decision-making.

Which Businesses Need ERP Software for the Plastic Moulding Industry?

ERP is essential for managing high-volume production, maintaining quality standards, and optimizing operations.

- Production Planning & Scheduling: Automate job scheduling and reduce downtime.

- Inventory & Raw Material Management: Monitor stock levels of polymers, additives, and other materials.

- Quality Control & Compliance: Ensure adherence to industry standards like ISO and FDA.

- Machine Maintenance & Monitoring: Track machine performance and schedule preventive maintenance.

- Order & Supply Chain Management: Streamline vendor coordination and order tracking.

- Cost Tracking & Budgeting: Monitor expenses to optimize profitability.

ERP helps smaller moulding businesses enhance efficiency while staying cost-effective.

- Affordable ERP Solutions: Tailored to small-scale operations with modular features.

- Job & Work Order Management: Automate task assignments for efficiency.

- Billing & Invoicing Automation: Simplify financial transactions and client billing.

- Material Usage Tracking: Reduce waste by monitoring raw material consumption.

- Compliance & Documentation: Maintain necessary regulatory documentation effortlessly.

ERP streamlines processes in specialized moulding units handling custom orders.

- Custom Order Management: Configure job settings for varying client requirements.

- Production Traceability: Track batch-wise production for better quality control.

- Integration with CAD/CAM Software: Connect design and production seamlessly.

- Energy Consumption Monitoring: Optimize energy usage and reduce costs.

- Real-Time Data & Reporting: Access insights on efficiency and material usage.

Packaging companies require ERP to manage high-speed production lines and diverse SKUs.

- Batch & Lot Tracking: Ensure consistency across production batches.

- Automated Labeling & Compliance: Meet industry-specific regulatory standards.

- Supply Chain Optimization: Reduce delays with real-time logistics tracking.

- Waste Management & Recycling: Implement sustainability measures.

- Multi-Location Production Management: Centralize operations across multiple plants.

ERP enhances efficiency for companies producing precision plastic parts for automotive and electronics industries.

- High-Precision Quality Management: Implement stringent QC measures.

- Demand Forecasting & Production Planning: Align production with market demand.

- Real-Time Inventory Updates: Prevent shortages or excess stock issues.

- Tooling & Mold Lifecycle Management: Track the usage and maintenance of molds.

- Advanced Analytics & Performance Metrics: Gain insights for process improvements.

How to Choose the Best ERP for Plastic Moulding Industry

- Understand Business Needs: Identify requirements for production, inventory, quality, and costing.

- Industry-Specific Features: Look for mold lifecycle management, raw material tracking, and waste control.

- Scalability & Customization: Ensure the ERP adapts to business growth and process modifications.

- Deployment Options: Choose between cloud, on-premise, or hybrid ERP based on security and accessibility.

- Ease of Use & Integration: Opt for an intuitive interface with seamless integration to existing systems.

- Cost & ROI Evaluation: Analyze software pricing, hidden costs, and long-term profitability.

- Vendor Support & Reputation: Check customer reviews, industry expertise, and post-implementation support.

ERP for Plastic Moulding Industry | Streamline Production & Operations

Boost efficiency with ERP software tailored for the plastic moulding industry. Automate workflows, track inventory, manage production, and ensure on-time delivery with ease.

Latest News

Get Updated With Latest Information